Membrane Bioreactor Technology

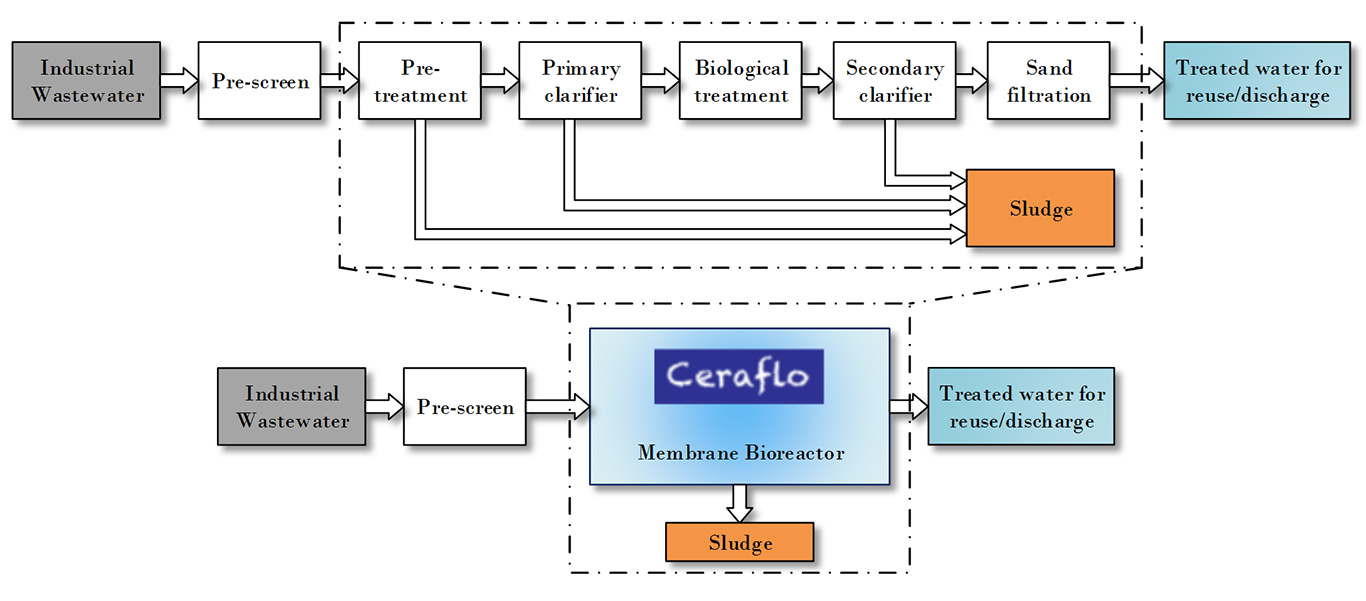

Conventional water treatment system vs Ceraflo® MBR

1. Principle

Ceraflo® Membrane Bioreactor (MBR) is a combination of moving bed bioreactor (MBBR) and conventional membrane bioreactor (MBR). The contaminants are removed by MBR through physisorption, biochemical reaction and physical filtration. Micro-bio-substrate is added to adsorb pollutants such as heavy metals. Besides that, it acts as a carrier to allow biofilm to grow. Contaminants such as COD, BOD, TN, TP and oil will be degraded by various bacteria consortium (e.g. aerobic bacteria, nitirifier, denitrifier, phosphorus accumulating bacteria, etc). The remaining contaminants will be rejected by the membrane and resulting in high quality product water.

2. Configuration

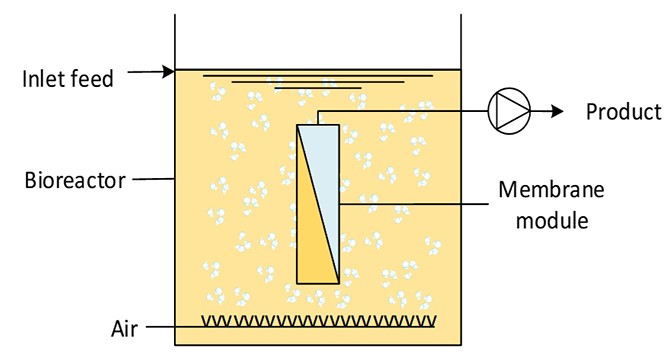

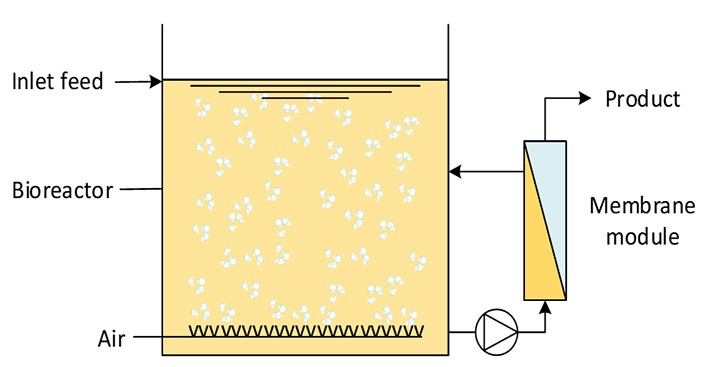

Similar with conventional MBR, it has the advantage of configuration flexibility. Ceraflo® MBR can be configured into (a) side-stream MBR, where membrane systems are arranged outside of biological tank, and (b) submerged MBR, where the membrane systems are submerged into biological tank.

|

|

3. Ceraflo MBR advantages and application

Ceraflo MBR system with modified hydrophilic UF membrane is specially designed to decrease membrane fouling rate and energy consumption. In addition, the micro-bio-substrates provides a large surface area for biofilm to grow quickly, becoming a granular bacteria consortium with non-sticky feature. The advantages are as below:

- - System is stable under drastic change in weather temperature

- - Bacteria incubating period 1 – 1.5 months (compared with traditional biological system which takes up to 3 months)

- - Around 0.8-1.0 kWh/m3 for domestic wastewater treatment

- - The media system complements well with the Ultra-Filtration membranes, allowing better cleaning regime resulting in enhanced flux rate at a sustained level (with lower fouling rates)

- - Only require tap water forward flushing or light CIP every 3-6 months.

- - MLSS can be up to 15000 ppm

- - COD can be allowed up to 2000 ppm

- - Can be customised with its configuration and operation

Check out our MBR product here