Membrane Technology

Ceraflo manufactures both ceramic and polymeric membrane.

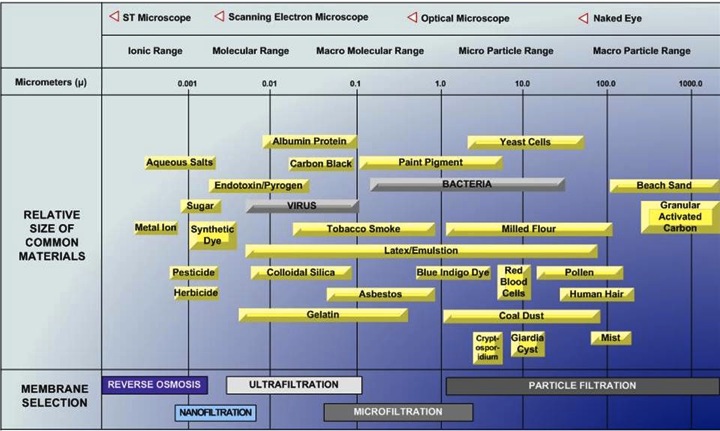

Our Ceramic is a proprietary multi-channel ceramic membrane plate designed to remove suspended particulates, colloidal material, bacteria and high molecular weight material with a pore size of 0.5 µm. We are the first Asian country outside Japan to manufacture multi-channel flat sheet ceramic membranes in commercial quantities.

We produce a large variety of polymeric hydrophilic modified ultrafiltration (UF) membranes, such as Polyacrylonitrile (PAN), polytetrafluoroethylene (PTFE) and Polyvinylidene Difluoride (PVDF) with pore size 0.02 µm. The large variety of polymeric membranes is able to accommodate all customers’ needs and produce sustainable water quality based on the economy, social and environment perspective.

To walk towards zero liquid discharge (ZLD), we also design, manufacture and operate Nanofiltration (NF) and Reverse Osmosis (RO) filtration system to produce high quality water.

Check out our membrane products here.

CERAFLO® CERAMIC AND POLYMERIC MEMBRANE PLATES/MODULES/SYSTEMS |

|

| Properties | Advantages |

Low cost |

Designed based on proprietary manufacturing know-how |

Small footprint |

Compact modules with high degree of flexible configurations and scalability |

Anti-fouling |

High resistant to both chemical and biological contaminants |

Hydrophilic |

Requires less energy during filtration cycles |

Thermal resistant |

Ability to withstand high temperature feed water |

Variable pore size |

Ability to design for various applications |

Low maintenance |

Less chemical and backflush cycles |