Drinking water

|

|

Source water

Surface water (Lake) in Yunnan Province, China.

Water clarification

Lake water quality is clarified using our Adsorptive Membrane Bioreactor (AMBR) technology. It is a combined technology of physical adsorption, MBBR and MBR.The product quality is able to meet 'Environmental quality standards for surface water GB3838-2002' Type III.

Water quality

| Parameter | Feed water quality | Product requirement | Actual product quality |

| COD (mg/L) | 25 - 60 | ≤20 | 10 - 13 |

| NH3-N (mg/L) | 0.2 - 0.5 | ≤1.0 | ≤1.0 |

| TN (mg/L) | 0.5 - 2.0 | ≤1.0 | 0.1 - 0.7 |

| TP (mg/L) | 0.02 - 0.10 | ≤0.05 | ≤0.05 |

Project details

| Project name | Lake water treatment |

| Location | Yunnan Province, China |

| Feed water quality | Surface Water Environmental Quality Standard GB3838-2002 Surface water type IV to V |

| Product quality | Surface Water Environmental Quality Standard GB3838-2002 Surface water type III |

| Treatment system | Ceraflo AMBR |

| Testing phase | Pilot test |

| Flow rate | 36 m3/day (1.5 m3/ hr) |

| Project commissioned | March 2019 |

Source Water

River water contaminated with domestic wastewater is pumped into EQ tank before filtration.

Water clarification

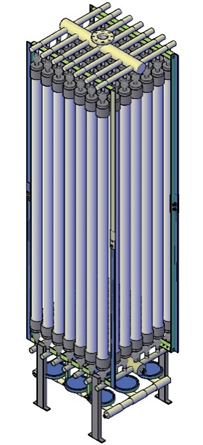

The river water is firstly clarified using our Anoxic-Oxic Moving Bed Bio-Reacotor (AO-MBBR) technology, which is an MBBR that gives both anoxic and aerobic environment for effective nutrient, BOD and COD removal.

Water is then further clarified with our UF membrane system to meet the Environmental quality standards for surface water GB3838-2002 CLASS III.

Project details

Feed and product quality

|

|

|

|

Source Water

Water is pumped from borehole wells into feed sumps and tanks before filtration.

Water clarification

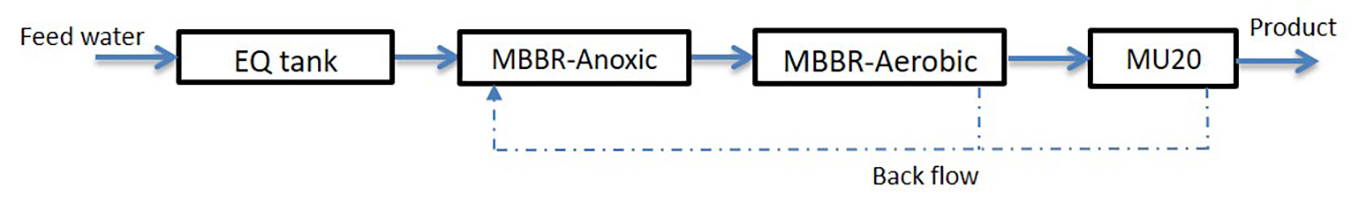

An Indonesia-based MNC was sourcing for solutions to improve the water quality supplied to their nurseries. Ceraflo’s water treatment system was chosen to improve the water quality supplied to the nurseries resulting in decreased mortality of young saplings. A combined capacity of 3600m3/day is supplied to the different nurseries at 3 locations.

Project details

| Project name | Borewell water clarification |

|---|---|

| Location | Indonesia |

| Treatment system | Location 1: MU50-850

Location 2: MU40-850 Location 3 & 4: MU30-850 x 2 sets |

| Testing phase | Full scale |

| Flow rate | Location 1: 50m3/hr,

Location 2: 40m3/hr, Location 3 & 4: 30m3/hr |

| Project commissioned | 3rd & 4th Quarter 2015 |

MU50-850 containerized beside feed sump with air blower and pre-treatment |

Nurseries |

Source Water

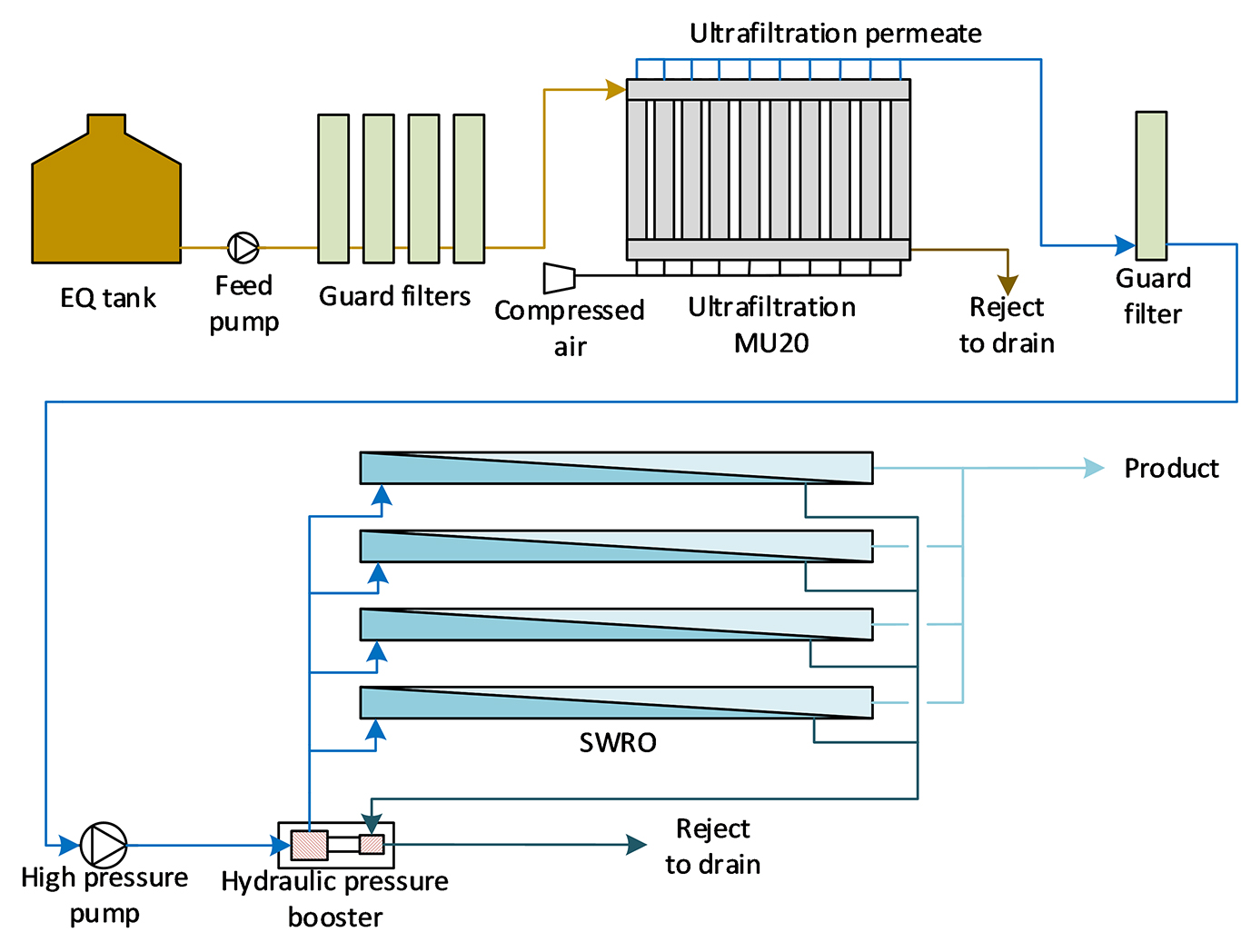

Hotel is located on an island and seawater will be drawn into a feed tank before feeding into the system.

Water clarification

Sea water is clarified using our proprietary UF membrane system which includes insert membrane and continuous purging protocol.

Clarified water is then sent through the high pressure RO system with energy recovery unit to remove the salt from the water.

The resultant permeate at 200 m3/d has a TDS <500 mg/l.

Project details

Feed and product quality

|

|

|

|

Wastewater

Source Water

Wastewater produced from industrial park is pumped into EQ tank before filtration.

Water clarification

Ceraflo designed and built a wastewater treatment system to treat industrial and domestic wastewater from auto parts factories. The total capacity is 500 m3/day.

Project details

|

|

|

|

Source Water

Produced water and flowback from the fracking oil field.

Water clarification

Water is pumped to PTFE hollow fibre membrane demo system to remove solids and oil to meet fracking water standard. No backflushing of membrane or dosing of chemicals is required. Only constant aeration is performed for constant cleaning.

|

|

|

|

|

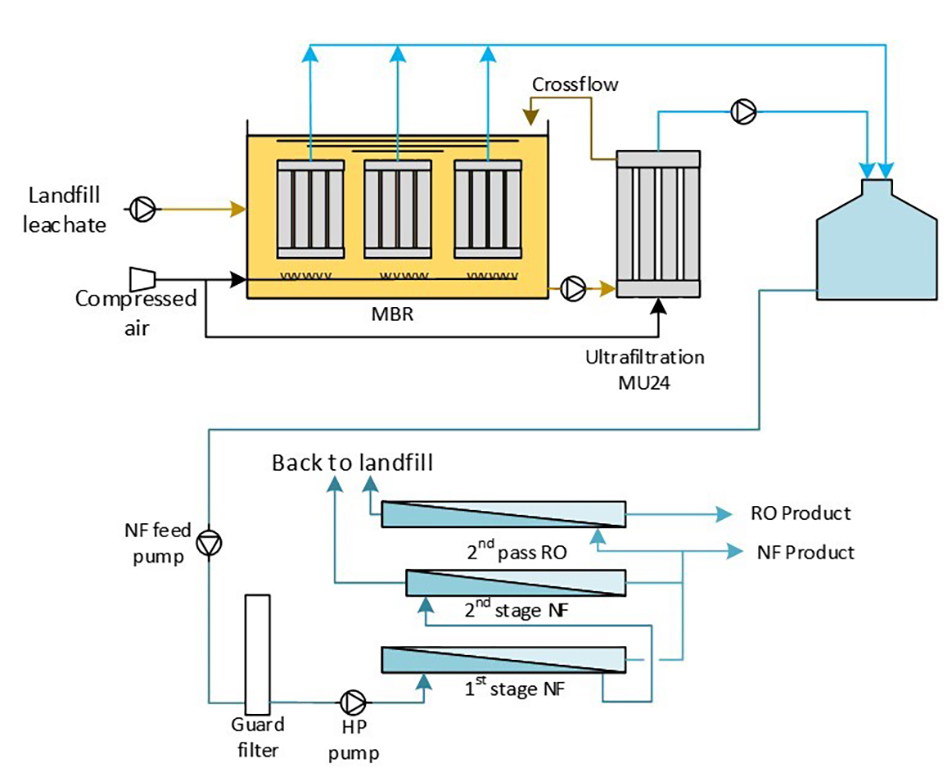

Ceraflo designed and built a landfill leachate treatment system in Guangdong Province, China. The technologies used in the treatment system are Membrane Bioreactor (MBR), Ultrafiltraion (UF), Nanofiltration (NF) and Reverse Osmosis (RO).

Project details

| Project name | Landfill leachate treatment |

| Location | Guangdong Province, China |

| Feed water quality | Landfill leachate |

| Product quality | In line with China- 'Standard for Pollution Control on the Landfill Site of Municipal Solid Waste GB 16889-2008' Table 2 |

| Flow rate | 100 m3/day |

| System | 40 feet Containerised MBR-NF-RO |

| Project Commissioned | May 2019 |

|

|